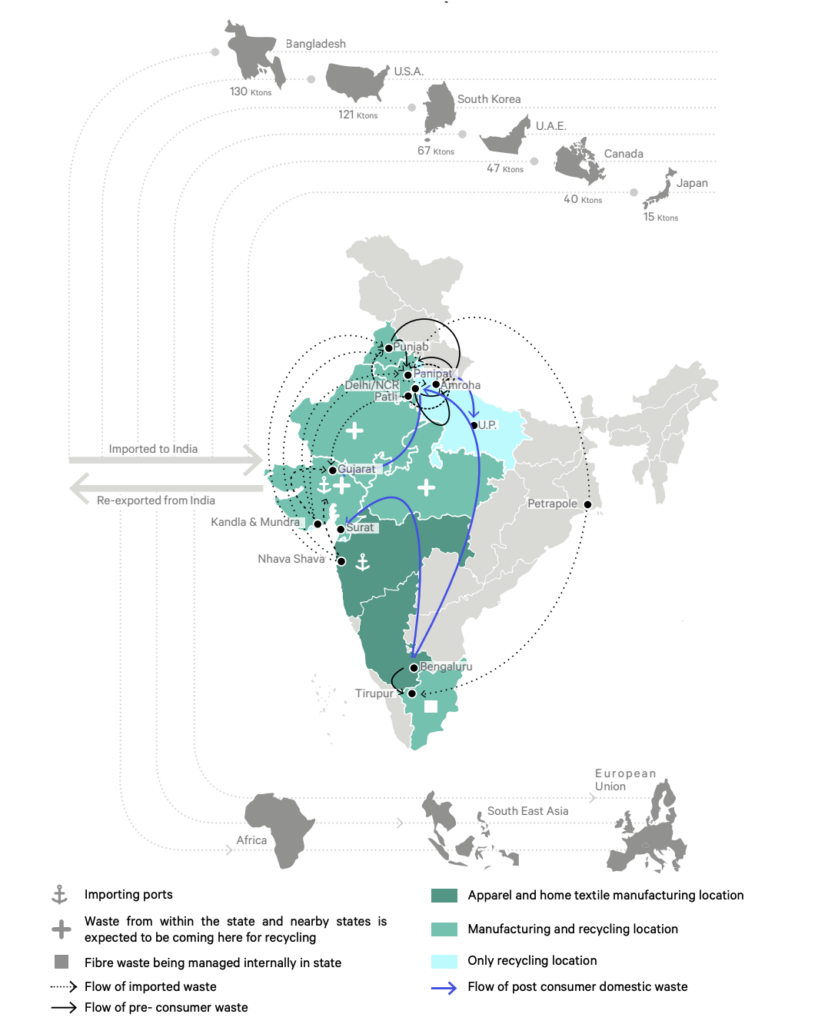

At the end of 2021 the Sorting for Circularity-India project was launched. Led by Fashion for Good and funded by Laudes Foundation, Reverse Resources has been the key partner to help mapping out the textile waste flows in India with our SaaS platform. We are now glad to share the “Waste to Wealth” report published in July 2022 to give overview of the challenges and opportunities India is facing with textile waste flows and the many nuances of the emerging circular economy in the country. We are very grateful for the great on-ground collaboration with Sattva Consulting and Saahas Zero Waste, who provided this comprehensive overview of the diverse, complex and dynamic Indian market.

From 2019-2020, the Indian Textile and Apparel industry was valued at USD 108.5 billion, forming 2% of total GDP, 12% of total exports. In addition to being an important stakeholder in textile and fashion production, India is also one of the few and largest mechanical recycling hubs in the world, with over 900 recycling units. While India possesses a huge mechanical recycling infrastructure and potential, the country has not been able to establish the complete circularity of textile wastes.

Approximately 7,793 ktons, or 8.5% of global textile waste, is accumulated in India every year. 59% of this waste finds its way back into the textile industry through reuse and recycling but only a fraction of this makes it back into the high-end global supply chains due to quality and visibility challenges. The remaining 41% is downcycled (19%), incinerated (5%) or ends up in a landfill (17%).

Out of total waste circulation, 51% comes from domestic post-consumer collection, 42% from pre-consumer sources, and only 7% is imported post-consumer waste.

The space where RR is currently most active in – helping textile-to-textile recyclers access cutting scraps from garment production transparently, or find post-consumer sorted by exact fibre composition – is quite similarly to other countries still rather inefficient. Majority of recycling is built up on the use of soft fibre waste from fabric production – the easiest type of waste that can be used by recyclers. This has been part of the fabric production practices since long because adding a share of recycled fibre into the products helps reduce the cost of yarn and fabric production rather efficiently. While 46% of pre-consumer waste is being recycled, ~86% of waste that consists of fibre waste, while 10% consists of cutting waste, and the remaining 4% from mill waste. This clearly highlights that a large percentage of cutting waste is going into other use cases.

~60% of waste made of cotton and cotton rich materials, making these materials highly valuable for the emerging textile-to-textile recycling sector globally.

You can download the full report from HERE

Stay tuned!