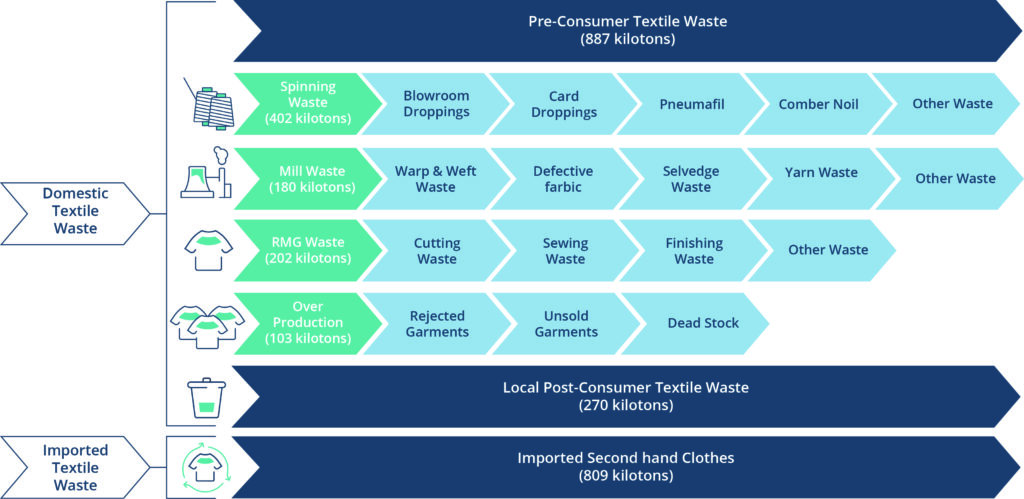

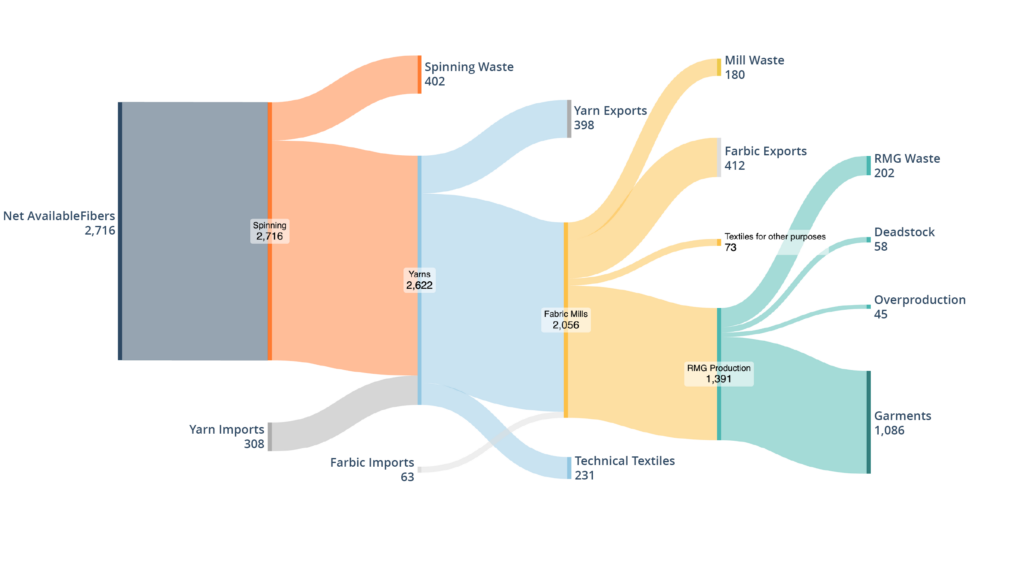

As a top textile producer, Pakistan must expand sustainably while managing its 887 kilotons of pre-consumer textile waste and 809 kilotons of imported second-hand clothing. Despite a strong recycling culture, the Pakistan’s textile recycling sector remains informal, limiting its circular economy potential. A new research finds that investment, digital tracking, and policy reforms could position Pakistan as a global leader in textile-to-textile recycling, boosting the economy while cutting waste.

A new *report “Comprehensive Overview of the Pakistan Textile Waste Industry“, provides the most comprehensive analysis of Pakistan’s textile waste landscape, offering critical insights into the country’s recycling potential and industry challenges. The findings highlight Pakistan’s position as a major player in textile recycling, with significant opportunities to scale textile-to-textile (T2T) recycling through improved waste management, investment, and supply chain development.

The Textile Industry’s Double-Edged Sword

Pakistan’s textile industry is a powerhouse, driving a significant portion of the country’s GDP and providing employment for millions. However, alongside its contributions, the industry also generates substantial waste, posing complex environmental and social challenges.

A Legacy of Recycling: Pakistan’s Role in Textile Waste Management

Pakistan has a long history of recycling, with Faisalabad as a key hub for processing textile waste. The country is also a major importer of second-hand clothing — 809 kilotons in 2023 alone — re-exporting a portion while repurposing some domestically. Despite its recycling culture, the sector largely operates informally, limiting efficiency and quality.

Types of Textile Waste Streams in Pakistan

The Scale of Textile Waste: Pre-Consumer and Post-Consumer Insights

Annually, Pakistan generates around 887 kilotons of pre-consumer textile waste from spinning, weaving, and garment production. Cotton-based materials dominate this waste stream. However, the recycling processes remain largely mechanical, with bleaching used to remove colors and blend fibers. Yet, most operations occur informally, lacking technological advancement and policy support.

Challenges and Barriers in Textile Recycling

The informal nature of Pakistan’s textile recycling sector creates numerous challenges — inefficient waste collection, contamination, and limited traceability being the most significant. High energy costs and outdated technology further hinder the production of quality recycled yarn. Policy gaps, including the absence of stringent recycling targets or alignment with global standards like Extended Producer Responsibility (EPR), exacerbate these issues.

Opportunities for Growth: Investing in Circular Solutions

Despite the challenges, there is immense potential to scale textile-to-textile (T2T) recycling. Investment in modern infrastructure, digital tracking of waste flows, and organised collection systems can help Pakistan become a leader in sustainable textile production. Leading manufacturers are exploring new opportunities for scaling T2T solutions.

“Pakistan’s textile sector already has a strong foundation for recycling, but there is immense potential to move beyond conventional methods. This report helps us identify key gaps and opportunities to transition towards high-value recycling solutions,” said Prof. Dr. Yasir Nawab from National Textile University.

Policy Reforms: Aligning with Global Standards

To unlock Pakistan’s textile recycling potential, aligning with international standards like EPR is crucial. The SMEP program supports this transformation by fostering collaboration between stakeholders and providing research-driven insights. The Fashion for Good “World of Waste” tool is also pivotal in uniting efforts to develop data on textile waste.

Building a Sustainable Future

By investing in new technologies, modernising supply chains, and embracing global best practices, Pakistan has the opportunity to become a central source of recycled materials. Not only will this reduce waste leakage, but it will also create economic opportunities and meet rising global demands for sustainable textile products.

*This research, conducted by Reverse Resources (RR) in collaboration with the National Textile University (NTU) Faisalabad and KnowTex, is part of the Sustainable Manufacturing and Environmental Pollution (SMEP) program, funded by the United Kingdom’s Foreign, Commonwealth & Development Office (FCDO) and implemented in partnership with the United Nations Conference on Trade and Development (UNCTAD). The report delivers actionable insights aimed at fostering a circular textile economy in Pakistan, reducing waste and environmental impact while unlocking economic opportunities.

To learn more, access the full report here.